Let’s discuss the question: how to align torque converter to flexplate. We summarize all relevant answers in section Q&A of website Myyachtguardian.com in category: Blog MMO. See more related questions in the comments below.

Table of Contents

Should there be a gap between torque converter and flexplate?

You should observe 1/8” (. 125”) to 3/16” (. 187”) of air gap between the torque converter mounting pads and flexplate before sliding the converter forward to attach it to the flexplate. If you have 1/8” – 3/16” air gap then you may proceed with sliding the torque converter forward and attaching it to the flexplate.

Do I need to shim my flexplate?

If there is a 1/4″ or more clearance between the converter and flexplate you need to shim it. Use washers that are the same thickness to get down to about 1/8″ clearance. You need some clearance for converter ballooning.

Installing torque converter to flex plate pt1

Images related to the topicInstalling torque converter to flex plate pt1

What happens if you put a Flexplate on backwards?

Putting it in backwards will effectively move the ring gear of the flexplate aft – and by the witness marks on the ring gear from the starter, it would appear that’s the case becuase it looks like it’s only partially engaging on the forward edges of the teeth – assuming the starter solenoid is pushing the starter gear …

What happens if torque converter is installed wrong?

When the torque converter starts malfunctioning, you may feel shuddering and even slipping in overdrive. You usually notice your car shuddering because it feels like it’s vibrating. Your car will vibrate even when you’re not going very fast. The shuddering makes the car lag and is very noticeable.

How much oil do you put in a torque converter?

When installing the converter onto the transmission, please pour approximately one quart of ATF (automatic transmission fluid) into the converter before installing into the transmission. Using a light grease, coat the transmission seal, front pump bushing, and converter neck.

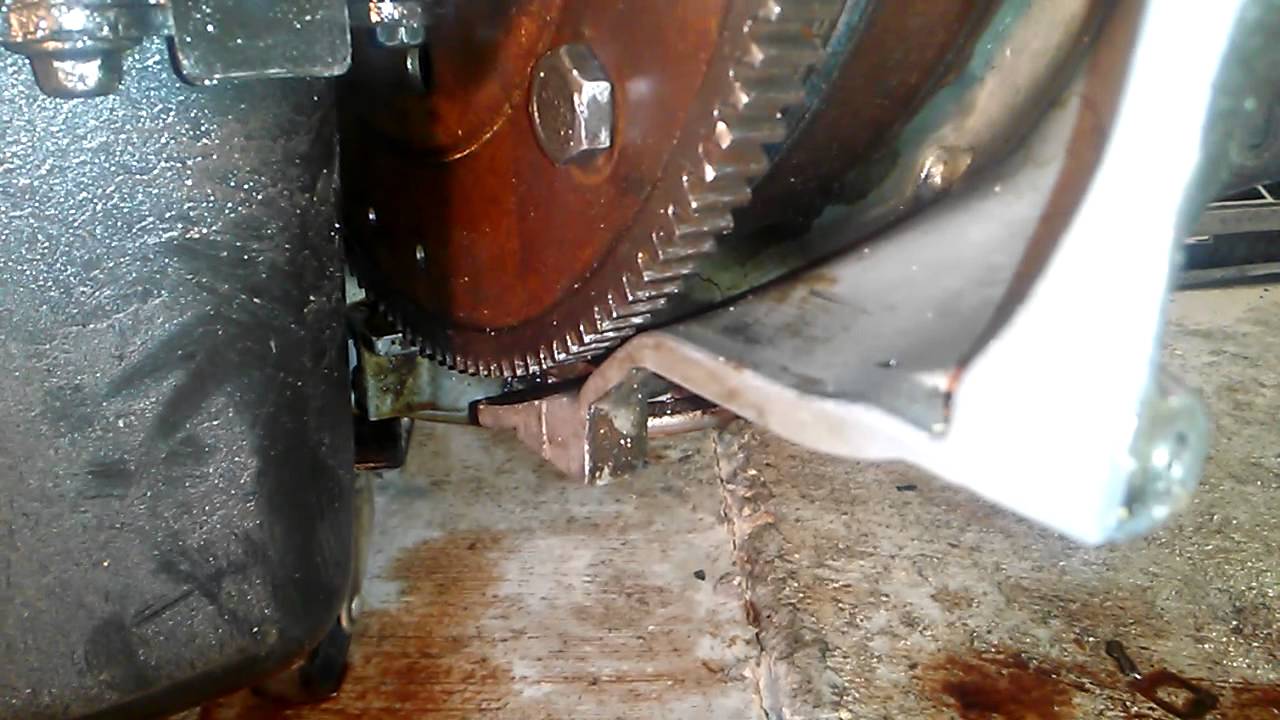

Quick Tip: Installing Torque Converter Bolts

Images related to the topicQuick Tip: Installing Torque Converter Bolts

How do you tell if a torque converter is in all the way?

My transmission guy told me a good piece of advice, he said if the converter is all the way back into the pump and the transmission is bolted to the engine, when you bolt the converter to the flywheel it should pull the converter forward 1/4″- 1/2″. This is a sure fire way to make sure it is in all the way.

What is ballooning a torque converter?

Balooning is a term used to describe the bearing or thrust washer surfaces at the front and back of the converter when they go out of parallel. The only way for this to happen is for the converter to be expanded by oil pressure which makes the converter taller that it was originally.

How do you check a torque converter before installing?

Put the pedal to the metal While pressing on the brake pedal, press the accelerator to the floor for two to three seconds. Don’t exceed five seconds, or you risk blowing out the transmission. The RPM the engine maxes out at is the stall speed.

how to bolt torque converter to flywheel after bucking tranny and motor together

Images related to the topichow to bolt torque converter to flywheel after bucking tranny and motor together

What is the pilot on a torque converter?

The torque converter pilot is a cold forged part, made from SAE 1018 material. The part is attached by heat welding onto the front side of the Torque Converter assembly. It’s important to explain how this part serves as a critical guide or “pilot”, during the installation of the Torque Converter.

Should a torque converter have play?

Make sure converter can rotate and has end-play. Converter must be free to move a minimum of 1/8″, but not more than 3/16″. If converter has no end-play, converter was installed improperly.

Related searches

- torque converter to flexplate gap

- symptoms of incorrectly installed torque converter

- how much space between flexplate and torque converter

- torque converter flywheel bolts wont line up

- what size are torque converter bolts

- how to align a torque converter

- how to tighten torque converter bolts

- torque converter to flexplate clearance

- torque converter tight against flexplate

- flex plate installed backwards

- how many torque converter bolts on 4l60e

- torque converter bolts 4l60e

Information related to the topic how to align torque converter to flexplate

Here are the search results of the thread how to align torque converter to flexplate from Bing. You can read more if you want.

You have just come across an article on the topic how to align torque converter to flexplate. If you found this article useful, please share it. Thank you very much.