Let’s discuss the question: howden screw compressor slide valve. We summarize all relevant answers in section Q&A of website Myyachtguardian.com in category: Blog MMO. See more related questions in the comments below.

Table of Contents

How does a slide valve work on a screw compressor?

Screw compressor have slide valve mechanism which is typically used to adjust the flow rate of fixed frequency drive (50Hz or 60Hz) compressor. The inlet gas is bypassed by moving the slide valve to discharge side of the screw rotor which are shown in Fig. 2.

What are the parts of a screw compressor?

- Rotary screw element. Drives the air to the outlet and creates the pressure.

- Compression chamber. …

- Inlet suction air filter. …

- Oil filter. …

- Anti-friction roller and ball Bearings. …

- Suction valve or load / unload valve. …

- Discharge valve. …

- Compressor motor.

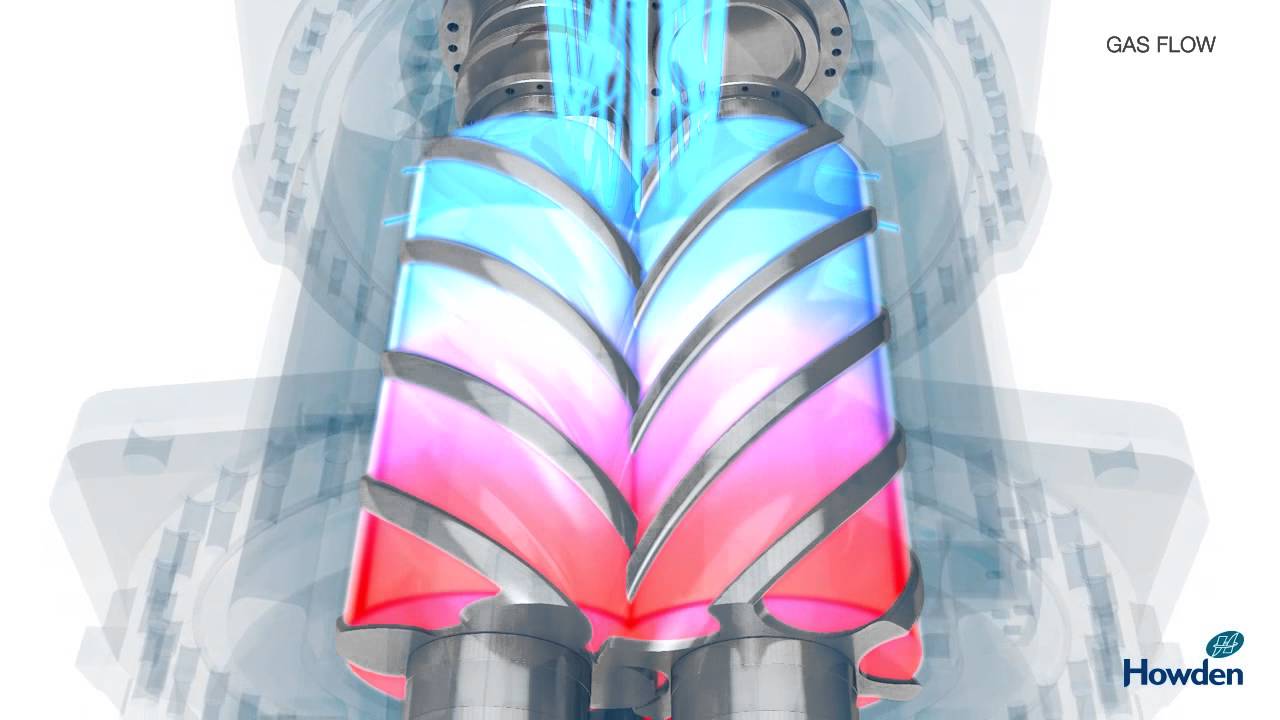

Screw Compressor animation | Howden

Images related to the topicScrew Compressor animation | Howden

What is the function of oil stop valve in screw compressor?

An oil stop valve prevents the compressor element from flooding with oil when the compressor stops.

Do screw compressors run constantly?

For screw compressors, the cooling systems are much better, so the compressors can run constantly with no issues. But running constantly usually means the units are not very efficient. Screw compressors have a few different ways to control the output to match the actual system flow.

Why oil is flooded in screw compressor?

In oil flooded screw compressor / oil injected screw compressor oil is injected to the compression chamber to cool and lubricate the compressor element and to reduce the return leakage to the intake.

Why do dry rotary screw type compressors have timing gears?

Rotary-screw compressors use two very closely meshing helical screws, known as rotors, to compress the gas. In a dry-running rotary-screw compressor, timing gears ensure that the male and female rotors maintain precise alignment without contact which would produce rapid wear.

What oil goes in a screw compressor?

Compressor Oil 68 is suitable for use in rotary vane and screw compressors. Compressor 68, 122 and 220 are effective as “once-through” lubrication of reciprocating compressor cylinders as well as crankcases and some types of rotary compressors.

What is air end in screw compressor?

It’s that part of the machine where the actual compression takes place. It is the heart of the rotary screw air compressor. Often, the compressor screw element is also called air-end. They are constant flow (volume) with variable pressure compressors.

How do rotary screw air compressors work?

Rotary screw air compressors operate by trapping air between two meshed rotors and reducing the volume of that trapped air as it moves down through the rotors. This reduction in volume results in compressed air, which can then be used to power air tools, inflate tires, or in numerous other applications.

How does a screw compressor function?

The basic principle of a screw compressor is as the male and female rotors are rotating in opposite direction they draw air in between them. As the air progresses along the rotors the air is compressed as the volume space between the rotors decreases, hence creating compressed air that is displace to the outlet.

What is minimum pressure valve in compressor?

The minimum pressure valve acts as a check valve preventing back flow of compressed air into the airend, retains a minimum pressure in the compressor system for lubrication, offers a restriction to avoid a collapse of the air-oil separation filter, and ensures a suitable velocity of flow across the air-oil separator …

What is the use of screw compressor?

The rotary screw compressor is a displacement compressor type where rotating screws are used to compress the air. Compared with a piston compressor, the screw compressor compresses air continuously without pulsation. It has high efficiency at full load and low efficiency when partially loaded.

Howden comp wrvi204 slide valve

Images related to the topicHowden comp wrvi204 slide valve

Can you use an air compressor while its running?

If your operation needs it, they can run 24/7, but like a piston unit they run when a pressure signal turns them on. Unlike most piston compressors, most rotary compressors idle before they shut down completely.

Is a screw compressor positive displacement?

Positive displacement compressors draw in and capture a volume of air in a chamber. They then reduce the volume of the chamber to compress the air. Reciprocating Piston Compressors, Rotary Screw Compressors, Rotary Vane Compressors, and Scroll Compressors are all positive displacement compressors.

How often should you drain your air compressor?

It is recommended that you drain your tank daily, whether it is manually or automatically. Water build up in your tank can cause the bottom of your tank to rust forcing you to invest in a new tank. If you find yourself forget about draining your tank, you should look into purchasing an electronic drain valve.

What is the difference between oil-free and oil-flooded screw compressors?

Unlike oil-free compressed air systems, oil-flooded compressors require specialized equipment, such as oil separators and filtration systems to minimize the threat of oil carryover from impacting other critical system components downstream.

Are rotary screw compressors oil-free?

Oil-Free Rotary Screw Compressors

Rotary screw compressors are positive displacement compressors. The principle of compression in oil-less rotary screw compressors is similar to that of oil-injected models, but without oil being introduced into the compression chamber.

How is screw compressor lubricated?

In an oil injected rotary screw compressor, oil is used for four main purposes. It is injected into the compression chamber to cool the machine, provide adequate lubrication of the moving parts, provide sealing and to aid with noise dissipation.

What is the difference between rotary and scroll compressor?

The rotary compressor has more power and can therefore cool more air than a scroll unit. Rotary compressors are therefore a better option in larger central air conditioning system but might be wasted in a smaller central unit or in a window air conditioner.

How many screws a screw type compressor have?

Screw compressors use two meshing helical screws, while piston air compressors use pistons driven by a crankshaft. Another difference is the moving parts as the screw compressor has two moving parts which are not in contact while the piston compressor has a lot of moving parts.

Which is better rotary or inverter compressor?

Conclusion. To conclude its highly recommended that you always opt for an AC which comes with inverter technology. Even when going for inverter it’s better to have twin/triple rotary compressors instead of one. Now with a good grasp about the compressors, your job of selecting a right AC has become more simplified.

Can I use 10W30 in my air compressor?

Can you use 10W30 in your air compressor? No. The recommendation by manufacturers of air compressors and the advice of air compressor experts is to use air compressor oils without detergents. Since 10W30 contains detergents, it should not be used.

Howden Screw Compressor

Images related to the topicHowden Screw Compressor

Why is compressor oil so expensive?

Unfortunately, compressor users pay a high price for fluid contamination because of unnecessary fluid and separator purchases, wasted energy consumption from high separator pressure drop, frequent maintenance and repairs, needless compressor downtime and excessive waste oil handling and disposal.

How much oil does a screw compressor need?

The air compressor system holds approximately 1 gallon (4L) of oil. Check the oil level at the sight glass on the front of the WHASP Tank. Continue adding oil until the level is correct.

Related searches

- how to replace drain valve on air compressor

- screw compressor refrigeration

- vane compressor

- screw compressor diagram

- dry screw vacuum pump working principle

- how to close drain valve on air compressor

- howden screw compressor manual pdf

- air compressor system

- Vane compressor

- screw air compressor

- how to open air compressor drain valve

- what is slide valve screw compressor

- screw compressor slide stop

Information related to the topic howden screw compressor slide valve

Here are the search results of the thread howden screw compressor slide valve from Bing. You can read more if you want.

You have just come across an article on the topic howden screw compressor slide valve. If you found this article useful, please share it. Thank you very much.